Using mGuard in the energy industry

Nigel Dawbarn, market segment manager - industry management and automation at Phoenix Contact, discusses the importance of secure connections for industrial control systems.

18th May 2018 by Networks

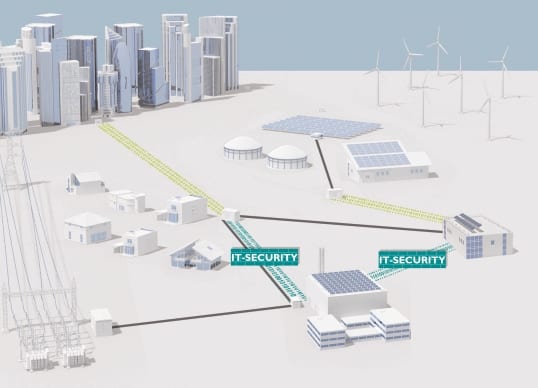

As smart grids and many other forms of distributed renewable energy now include battery systems, installed industrial wireless communication is a necessity. We need to ensure that our infrastructure control equipment is able to securely interact over a large geographical area. In order to do this, wired or fibre communication is just not practical, as remote communication is required. The answer is simple; use a radio system or mobile communication, connect all the local control units and report back to the central location. By using 3G or 4G you can get immediate information about how your equipment/plant is running and if needs be even control some remote processes.

As we review distributed systems and installations with customers, we have discovered there are many more functions requiring an industrial connection such as; data collection, remote control and fault finding. But this can leave distributed systems vulnerable. Phoenix Contact has worked with customers for over 10 years in order to develop a deep understanding of cyber security for industrial control systems, all the way up to major infrastructure projects.

Your requirements

We understand you need to be able to gain access to your data, gain control of systems remotely and be able to run diagnostics on your distributed assets. But you also need to be aware of vulnerabilities and security risks of distributed systems. Industrial network security is a growth market not appropriately served by conventional office equipment and therefore requiring alternative industry suitable solutions. The availability of data from facilities and processes has the highest security requirement on top of integrity and confidentiality of data communication as further objectives.

Failures and downtimes reduce productivity, cause economic damage and result in a loss of trust with customers and the public. Therefore the networking of distributed asset and critical infrastructure has to rely on protected local industrial networks and secure remote connections via IP networks such as the Internet. We believe we have created the best solution for this.

Our solution

The mGuard portfolio was specifically developed for use in industrial environments. The mGuard products combine the properties of a stateful inspection including firewall and filtering incoming and outgoing connections. This is based on a custom defined rule set to the capability of secure and confidential communication through encrypted virtual private networks (VPNs). In addition, they can monitor the integrity of industrial PCs to protect against malware attacks. mGuard security appliances integrate easily with new industrial systems. mGuard also lend themselves perfectly to retrofitting for the protection of existing production lines or individual critical automation components.

For more information, get in touch on or call 01952 681700

Comments

Login on register to comment

Related content

Power

Utilities mobilise coronavirus vulnerability support

£800,000 of support has been offered to support those struggling as a result of the pandemic

Power

ENA champions network key workers in new campaign

Trade body justifies continued presence of network staff in customer communities

Power

Surge in popularity for ‘Power Up’ safety website as parents teach at home

UK Power Networks' free website designed to help children stay safe around electricity has seen its visitor numbers rise by more than 90%

Related supplier content

![‘Learning by doing’ on the road to net zero [test product]](https://networksonline.s3.amazonaws.com/products/images/3.jpg)

People & Skills

‘Learning by doing’ on the road to net zero [test product]

DSO director Andrew Roper discusses 'Learning by doing'

Power

Load patterns and lockdown: how Covid-19 is impacting electricity networks

Insights into dynamics on the low voltage network as the outbreak unfolds

Downloads

Protect electrical equipment from insulation failure

Insulation faults are a major cause leading to the eventual failure of electrical equipment. Partial discharge (PD) is a very reliable indicator of developing insulation faults. Regular PD testing allows users to detect and analyze PD activity